21-30 / 22747 hits

"Proposal of camera cleaning unit for automobiles Small DC pump (micropump mechanism / structural design) / housing molding / assembly ① ADAS driving support & security Back monitor parts for driving support system ② Small DC pumps (micro pumps) are proposed from the mechanical and structural design and produced at our factory. ③ Some of the resin molded products, (including housing molding) are produced at our factory. Features High flow rate, high pressure, optimal unit design (1) Achieve cleaning power with high flow rate and high pressure. (2) Further noise reducing and vibration by designing the mechanism and structure of the unit. Application Automobile parts, cleaning pump unit for back monitor For cleaning camera lenses Improve monitor visibility * We will respond promptly to inquiries □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□ TADA PLASTIC INDUSTRIAL CO.,LTD. 2-12-8, Tsudo, Fujiidera Shi, Osaka, Japan 583-0037 TEL:0081-729540981 http://www.tadapla.co.jp Ideas and technology that lead to innovation Fusion technology Injection molding Urethane foam Micro pump Precision rubber molding □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□

| Main 3 products | Compact DC pump Injection molding Urethane foam |

|---|---|

| Type of manufacturing | Transportation equipment Electronic parts Medical equipment |

| Recommended manufacturing category |

1:Mass production - Plastic - PU (polyurethane) 2:Mass production - Plastic - Expansion molding 3:Mass production - Plastic - GFRP (glass fiber reinforced plastic) 4:Mass production - Plastic - Gas injection 5:Mass production - Plastic - Injection molding 6:Mass production - Plastic - 60 - 300 t 7:Mass production - Plastic - PPS (polyphenylene sulfide) 8:Mass production - Plastic - CFRP (carbon fiber reinforced plastic) 9:Mass production - Plastic - PBT (polybutylene terephthalate) 10:Mass production - Plastic - Elastomer |

[Prototypes] Quick delivery without the use of molds! [Material] Iron Galvanized steel plate SECC [Size] t=2.0mm Product size: 360.5 x 46 x 69 [Lot] 1 to 50 [Accuracy] ±0.1 to ±0.5 [Processing method] Programming → Laser processing → Finishing → Countersink burring → M4 tapping → M3 tapping → Hemming (seam) → Bending [Industry/Application] Electrical parts Bracket used for part of the upper housing [Feature] This prototype product is utilized in electrical-related products. We have experience in handling prototypes for sheet metal processing from one piece. The outside perimeter of this product is finished after laser processing, and bending is performed after burring and tapping. As shown in the photo, there are several bends and the U-shaped tip is bent further inward, thus bending it into the product shape will be impossible if the order of bending is incorrect. We delivered this prototype within a week after receiving the order. We are pleased to discuss with you about your needs. Starting with a single prototype, please do not hesitate to contact us if you are experiencing any difficulties with prototypes, presses, or sheet metal. Zaou Seisakusho Co., Ltd. is a parts manufacturer that specializes in precision sheet metal processing by laser processing and press processing with a maximum capacity of 300 tons. In addition, in order to satisfy our customers' QCD, the biggest feature is that we are doing one-stop from mold making to press work in-house. As a post-press process, we comprehensively support caulking, tapping, spotting, welding, assembly, etc. We are currently working on improving our sales support. ◇Contact us◇ 225 Osawa Sengoku, Kaminoyama-shi, Yamagata 999-3122 TEL: +8123-672-2237 FAX: +8123-672-2418 https://www.zao-press.jp/ E-mail: y-suzuki@zao-press.co.jp Please contact Sales Department (PIC:Suzuki)

| Main 3 products | Automotive parts Copying machine, OA parts related Electrical parts |

|---|---|

| Type of manufacturing | Office automation equipment Transportation equipment Medical equipment |

| Recommended manufacturing category |

1:Mass production - Metal press - Progressive press (80 - 200 t) 2:Designing - Mold designing - Progressive die designing (auto) 3:Designing - Mold designing - Progressive die designing (light electrical) 4:Designing - Mold designing - Drawing metal press die designing 5:Designing - Mold designing - General metal press die 6:Mass production - Metal press - Single press (80 - 200 t) 7:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 8:Development and production of prototype/Small-scale production - Machining - Tapping 9:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 10:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Robot welding |

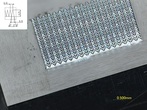

<<Small four-sided pyramids fabricated by Profile grinder>> We made small four-sided pyramids by Profile grinder. In order to realize smart mobility including autonomous driving, various electronic parts related to autonomous driving are required. At our company, we are involved in the design and production of the molds, devices, jigs and tools that are necessary to manufacture these electronic components. Please feel free to contact us when manufacturing electronic parts such as automatic driving. Material : STAVAX (Stainless steel X30Cr13 similar) 52±1 HRC Width of pyramid : 0.1mm Height of pyramid : 0.25mm Tolerance : ±0.002mm If you need a high precision and skall products, please contact us! <For inquiries, please contact here> Headquarter Sales Department TEL: +81-143-55-5293 FAX: +81-143-55-5295 sales@chimera.co.jp

| Main 3 products | Molding (plastic) dies, press dies, various mold components processing, precision metal machining [design, manufacture, testing] In order to meet needs for quick delivery, we stock various die materials such as NAK, SKS, SKD, high speed steel and ultra-hard materials. With our high speed cutting machining center, |

|---|---|

| Type of manufacturing | Audio-video equipment Office automation equipment Electronic parts |

| Recommended manufacturing category |

1:Die manufacturing - Plastic mold - Part processing 2:Designing - Mold designing - Injection molding die 3:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 4:Development and production of prototype/Small-scale production - Grinding processing - Jig boring 5:Development and production of prototype/Small-scale production - Grinding processing - Jig grinding 6:Die manufacturing - Press die - Plate machining 7:Die manufacturing - Press die - Die set machining 8:Die manufacturing - Plastic mold - Core and cavity machining 9:Die manufacturing - Plastic mold - Thin wall injection molding die 10:Die manufacturing - Plastic mold - Cassette-type molding die |

| Type of manufacturing | Heavy electric machinery Industrial machinery Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Mass production - Sheet-metal processing - Can making (more than 5m) 2:Surface treatment - Other surface treatment - Sound blast 3:Surface treatment - Other surface treatment - Shot blast 4:Surface treatment - Coating - Airless spray coating 5:Product manufacturing - Production property - Energy-saving equipment/Automatic instrument manufacturing 6:Designing - Industrial equipment designing - Carrier machine designing 7:Product manufacturing - Production property - Other industrial machinery manufacturing 8:Surface treatment - Coating - Metal coating 9:Mass production - Sheet-metal processing - Painting process 10:Development and production of prototype/Small-scale production - Prototype processing - Chassis prototype manufacturing |

| Type of manufacturing | Machine tools Measuring machinery Industrial machinery |

|---|---|

| Recommended manufacturing category |

Ensure the cleanliness and safety of your workplace with Grind Dresser GRM, a dust collector for grinding machines. Removes dust and mist at the same time, improving work efficiency. The Grind Dresser GRM dust/mist collector is a high-performance dust collector designed specifically for grinding machines. Both dust and mist can be removed efficiently, greatly improving the working environment in factories. This product is easy to operate and has high dust collection efficiency, and is specifically designed to meet the needs of the metalworking and woodworking industries. Features Immediate start-up: Just install the duct and start using it immediately. Mobility: Equipped with casters for easy movement to different work areas. Explosion-proof motor: Explosion-proof motor available as an option (please contact us for details). Airflow Adjustment: Comes with adjustment functions including inverter to meet different working conditions. specification Applicable equipment: grinding machine Dust collection ability: simultaneous removal of dust and mist Additional features: casters, adjustable airflow, optional anti-explosion motor

| Main 3 products | construction development of the industrial field |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 2:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 3:Mass production - Sheet-metal processing - Deburring process 4:Development and production of prototype/Small-scale production - Sheet-metal processing - Bending (hydraulic) 5:Mass production - Sheet-metal processing - Pipe processing 6:Mass production - Sheet-metal processing - Sheet metal prototype manufacturing 7:Mass production - Sheet-metal processing - NC set press 8:Mass production - Sheet-metal processing - Pipe bender processing 9:Development and production of prototype/Small-scale production - Sheet-metal processing - Bending (servo) 10:Mass production - Sheet-metal processing - Can-making |

| Type of manufacturing | Transportation equipment Industrial machinery Construction material |

|---|---|

| Recommended manufacturing category |

2:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 3:Development and production of prototype/Small-scale production - Blank cutting - Laser and turret punch press processing 4:Parts manufacturing - Spring - Thin leaf spring 5:Development and production of prototype/Small-scale production - Machining - Spinning 6:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 7:Development and production of prototype/Small-scale production - Blank cutting - Nitrogen cutting |

| Type of manufacturing | Heavy electric machinery Machine tools Industrial machinery |

|---|---|

| Recommended manufacturing category |

1:Mass production - Forging - Press forging 2:Parts manufacturing - Machinery part - Gear manufacturing 3:Parts manufacturing - Machinery part - Valve manufacturing 4:Parts manufacturing - Machinery part - Crank shaft manufacturing 5:Assembly/Inspection - Inspection - Forging 6:Mass production - Forging - Free forging 7:Material - Steel component distribution - Steel forgings |

Perfectly remove the water-soluble processing oil FGE350 from SUS processed goods. The combination of e-Clean 21C-5 and e-Clean 21N realizes consistent quality management from cleaning to drying. Overview Aluminum water-soluble processing oils play a crucial role in the manufacturing process of SUS processed goods, but to ensure the quality and performance of the products, these oils must be completely removed. The cleaning process specialized for Yushiro Chemical Industry Co., Ltd.'s FGE350, involving an immersion shaking cleaning with e-Clean 21C-5 followed by ultrasonic cleaning with e-Clean 21N in a two-step process, was developed to meet these requirements. After cleaning, the products undergo a strict quality evaluation through visual inspection and swab wiping tests (×5 microscope) before being shipped to the market. Features - Two-step cleaning process: The combination of e-Clean 21C-5 and e-Clean 21N efficiently removes aluminum water-soluble processing oils. - High cleaning effectiveness: The synergistic effect of immersion shaking cleaning and ultrasonic cleaning thoroughly removes stubborn dirt. - Safe and environmentally friendly: Uses low-toxicity cleaning solutions, providing a cleaning process that considers both worker and environmental safety. - Strict quality control: Ensures consistency in cleaning quality through visual inspection and swab wiping tests (×5 microscope). Specifications - Cleaning solutions: e-Clean 21C-5 → e-Clean 21N - Items to be cleaned: SUS processed goods - Contaminants: FGE350 by Yushiro Chemical Industry Co., Ltd. - Cleaning method: Immersion shaking (e-Clean 21C-5) → Ultrasonic cleaning (e-Clean 21N) → Natural drying - Evaluation method: Visual inspection and swab wiping test (×5 microscope) This cleaning method ensures the complete removal of the aluminum water-soluble processing oil FGE350 used in SUS processed goods, guaranteeing the high quality of the products. The e-Clean 21 series of cleaning solutions sets a new standard in the industry.

| Main 3 products | Industrial chemicals cleaning agent cleaning machine |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

21-30 / 22747 hits