1-10 / 22924 hits

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 2:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 3:Mass production - Sheet-metal processing - Deburring process 4:Development and production of prototype/Small-scale production - Sheet-metal processing - Bending (hydraulic) 5:Mass production - Sheet-metal processing - Pipe processing 6:Mass production - Sheet-metal processing - Sheet metal prototype manufacturing 7:Mass production - Sheet-metal processing - NC set press 8:Mass production - Sheet-metal processing - Pipe bender processing 9:Development and production of prototype/Small-scale production - Sheet-metal processing - Bending (servo) 10:Mass production - Sheet-metal processing - Can-making |

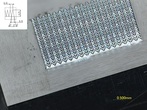

<<Small four-sided pyramids fabricated by Profile grinder>> We made small four-sided pyramids by Profile grinder. In order to realize smart mobility including autonomous driving, various electronic parts related to autonomous driving are required. At our company, we are involved in the design and production of the molds, devices, jigs and tools that are necessary to manufacture these electronic components. Please feel free to contact us when manufacturing electronic parts such as automatic driving. Material : STAVAX (Stainless steel X30Cr13 similar) 52±1 HRC Width of pyramid : 0.1mm Height of pyramid : 0.25mm Tolerance : ±0.002mm If you need a high precision and skall products, please contact us! <For inquiries, please contact here> Headquarter Sales Department TEL: +81-143-55-5293 FAX: +81-143-55-5295 sales@chimera.co.jp

| Main 3 products | Molding (plastic) dies, press dies, various mold components processing, precision metal machining [design, manufacture, testing] In order to meet needs for quick delivery, we stock various die materials such as NAK, SKS, SKD, high speed steel and ultra-hard materials. With our high speed cutting machining center, |

|---|---|

| Type of manufacturing | Audio-video equipment Office automation equipment Electronic parts |

| Recommended manufacturing category |

1:Die manufacturing - Plastic mold - Part processing 2:Designing - Mold designing - Injection molding die 3:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 4:Development and production of prototype/Small-scale production - Grinding processing - Jig boring 5:Development and production of prototype/Small-scale production - Grinding processing - Jig grinding 6:Die manufacturing - Press die - Plate machining 7:Die manufacturing - Press die - Die set machining 8:Die manufacturing - Plastic mold - Core and cavity machining 9:Die manufacturing - Plastic mold - Thin wall injection molding die 10:Die manufacturing - Plastic mold - Cassette-type molding die |

| Main 3 products | Mobile containers for on-site use Powder conveying system |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

| Type of manufacturing | Audio-video equipment Home electrical appliances Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Sheet metal protocol manufacturing 2:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing 3:Development and production of prototype/Small-scale production - Sheet-metal processing - Thin wall (Thickness: 0.5 or less)/small-size sheet metal machining 4:Development and production of prototype/Small-scale production - Prototype processing - Simple mold, prototype mold 5:Development and production of prototype/Small-scale production - Prototype processing - Bending 6:Development and production of prototype/Small-scale production - Jig manufacturing - General jig manufacturing 7:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 8:Development and production of prototype/Small-scale production - Blank cutting - Precision cutting 9:Development and production of prototype/Small-scale production - Prototype processing - Prototype/Small-lot molding 10:Development and production of prototype/Small-scale production - Machining - Automatic lathe |

High-quality parts manufacturing and assembly services by a specialist company in precision parts assembly. Our high-precision products improve your productivity and reliability. We are a specialist company focusing on the manufacturing and assembly of precision parts. Utilizing the latest equipment and advanced technology, we manufacture and assemble high-quality parts swiftly and accurately. We produce precision parts used in various industries such as electronics, automotive, and household appliances. Our products boast high reliability and durability, making them the optimal choice to enhance your product quality and productivity. Features High-Precision Manufacturing: Utilizing state-of-the-art equipment and technology, we manufacture parts with extremely high precision. Quick Response: Efficient production lines and skilled staff enable us to deliver on short deadlines. Customization: We offer custom-made parts manufacturing tailored to our customers' needs. High Durability: Using materials with excellent wear and corrosion resistance, we provide long-lasting products. Strict Quality Control: All products are manufactured under strict quality control, ensuring high reliability. Specifications Materials: Steel, stainless steel, aluminum, copper, brass, etc. Sheet Thickness: Capable of handling thicknesses from 0.2mm to 2.0mm Manufacturing Tolerance: Within ±0.01mm Surface Treatments: Capable of various surface treatments such as electropolishing, anodizing, plating, etc. Inspections: Precision inspections using 3D measuring machines, X-ray inspection devices, etc. Supported Sizes: Capable of handling sizes from millimeters to submicron units Applications Electronics: High-precision connectors, switches, sensor parts, etc. Automotive: Precision engine parts, electronic control unit parts, etc. Household Appliances: High-precision components, switch parts, etc. Improve your product quality and productivity with our high-quality precision parts. Please download the PDF for more details or feel free to contact us.

| Main 3 products | Stamping part Coiling spring Plastic injection parts |

|---|---|

| Type of manufacturing | Home electrical appliances Electronic parts Medical equipment |

| Recommended manufacturing category |

| Type of manufacturing | Industrial machinery Construction material Medical equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Bending (over 3.0 m) 2:Development and production of prototype/Small-scale production - Sheet-metal processing - Chassis manufacturing 3:Assembly/Inspection - Assembly - Industrial machinery assembly 4:Product manufacturing - Construction and civil engineering machinery manufacturing - Construction and civil engineering material manufacturing 5:Mass production - Sheet-metal processing - Mirror surface material processing 6:Development and production of prototype/Small-scale production - Machining - Planer machining |

| Main 3 products | Compressor Vacuum pump Painting equipment |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

| Type of manufacturing | Heavy electric machinery Jigs and tools Industrial machinery |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 2:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 3:Development and production of prototype/Small-scale production - NC machining - Machining (horizontal) 4:Development and production of prototype/Small-scale production - Machining - General-purpose lathe machining 5:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 6:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 7:Development and production of prototype/Small-scale production - Machining - Thread-cutting 8:Surface treatment - Heat treatment - Quenching 9:Surface treatment - Coating - Metal coating 10:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining |

| Type of manufacturing | Industrial machinery Transportation equipment Medical equipment |

|---|---|

| Recommended manufacturing category |

1:Mass production - Plastic - Vacuum molding 2:Mass production - Plastic - Handles small-scale production 3:Mass production - Plastic - Injection molding 4:Auto parts manufacturing - Body part - Door mirror 5:Auto parts manufacturing - Body part - Other body parts 6:Surface treatment - Printing and others - Silk screen printing 7:Surface treatment - Coating - Resin coating 8:Mass production - Plastic - Special shape extrusion molding 9:Surface treatment - Printing and others - Pad printing 10:Mass production - Plastic - FRP molding (RTM, BMC, SMC) |

[Prototypes] Quick delivery without the use of molds! [Material] Iron Galvanized steel plate SECC [Size] t=2.0mm Product size: 360.5 x 46 x 69 [Lot] 1 to 50 [Accuracy] ±0.1 to ±0.5 [Processing method] Programming → Laser processing → Finishing → Countersink burring → M4 tapping → M3 tapping → Hemming (seam) → Bending [Industry/Application] Electrical parts Bracket used for part of the upper housing [Feature] This prototype product is utilized in electrical-related products. We have experience in handling prototypes for sheet metal processing from one piece. The outside perimeter of this product is finished after laser processing, and bending is performed after burring and tapping. As shown in the photo, there are several bends and the U-shaped tip is bent further inward, thus bending it into the product shape will be impossible if the order of bending is incorrect. We delivered this prototype within a week after receiving the order. We are pleased to discuss with you about your needs. Starting with a single prototype, please do not hesitate to contact us if you are experiencing any difficulties with prototypes, presses, or sheet metal. Zaou Seisakusho Co., Ltd. is a parts manufacturer that specializes in precision sheet metal processing by laser processing and press processing with a maximum capacity of 300 tons. In addition, in order to satisfy our customers' QCD, the biggest feature is that we are doing one-stop from mold making to press work in-house. As a post-press process, we comprehensively support caulking, tapping, spotting, welding, assembly, etc. We are currently working on improving our sales support. ◇Contact us◇ 225 Osawa Sengoku, Kaminoyama-shi, Yamagata 999-3122 TEL: +8123-672-2237 FAX: +8123-672-2418 https://www.zao-press.jp/ E-mail: y-suzuki@zao-press.co.jp Please contact Sales Department (PIC:Suzuki)

| Main 3 products | Automotive parts Copying machine, OA parts related Electrical parts |

|---|---|

| Type of manufacturing | Office automation equipment Transportation equipment Medical equipment |

| Recommended manufacturing category |

1:Mass production - Metal press - Progressive press (80 - 200 t) 2:Designing - Mold designing - Progressive die designing (auto) 3:Designing - Mold designing - Progressive die designing (light electrical) 4:Designing - Mold designing - Drawing metal press die designing 5:Designing - Mold designing - General metal press die 6:Mass production - Metal press - Single press (80 - 200 t) 7:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 8:Development and production of prototype/Small-scale production - Machining - Tapping 9:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 10:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Robot welding |

1-10 / 22924 hits