- Telephone number: +81-79-447-4561

- FAX: +81-79-448-8001

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Simultaneous 5-axis machining( Development and production of prototype/Small-scale production / Machining ) |

|---|---|

|

|

5-face/5-axis machining( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Handles 3D processing( Development and production of prototype/Small-scale production / NC machining ) |

|

|

Aluminum alloy( Mass production / Mechanical processing ) |

|

|

Nickel alloy( Development and production of prototype/Small-scale production / Machining ) |

|

|

Titanium alloy( Development and production of prototype/Small-scale production / Machining ) |

|

|

Ultra-thin( Mass production / Mechanical processing ) |

Icon

Company info

| Company name | Dainichi Manufacturing Co., Ltd. | Website URL | https://5jiku.net/ |

|---|---|---|---|

| Street address |

Takasago Hyogo Japan

[See map] |

Person in charge | Emi Taneichi |

| Telephone number | +81-79-447-4561 | Fax number | +81-79-448-8001 |

| Capital | 30,000,000 JPY | Employees | 75 |

| Annual sales | Unregister | EMIDAS Member Number | 71607 |

| Type of manufacturing | Heavy electric machinery / Industrial machinery / Transportation equipment | ||

| Main 3 products |

|

||

PR message

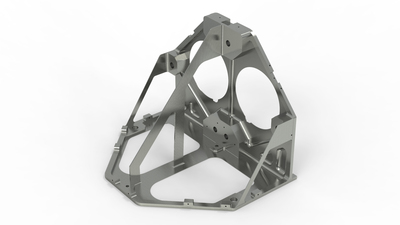

We pursue processing that takes advantage of both quality and cost by simultaneous 5-axis control machining centers and compound lathes were introduced one after another and processing 3D shaped workpieces using 3D-CAD/CAM and process integration.

We have trained about 10 production engineers to use CAM, and we have built a system that allows us to launch multiple types of new 3D shapes such as aircraft parts in a short period of time. We also respond to requests for prototype production in general industrial fields.

In order to meet the ever-shortening development lead time, we are responding to short delivery times by making full use of 5-axis machines.

On the other hand, we are also actively introducing automated equipment for 5-axis machining, and also handle the short-term start-up of mass-produced products.

In terms of quality control, we have already acquired JISQ9100 certification. We handle a wide range of products, from accuracy assurance for single products to variation management for mass-produced products.

Most recent update:2024-10-14

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Simulation | 3D modeling |

| Designing | Data creation (3D scan) | Data creation (3D scan) |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Deep hole drilling Thread-cutting Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Aluminum alloy Copper alloy Titanium alloy Nickel alloy Machining (resin) Sintered metal Sintered metal Simultaneous 5-axis machining Lathe machining (resin) Casting Titanium Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) Additional-axis machining NC lathe machining 5-face/5-axis machining Five-face machining Combined lathe machining Machining (horizontal) Handles 2.5-dimensional processing Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding Cylindrical grinding |

| Development and production of prototype/Small-scale production | Prototype processing | Aluminum die-casting |

| Mass production | Mechanical processing | Machining NC milling machining NC turning machining Tapping machining Five-face/axes machining Complex turning machining Wire machining Screw cutting machining Micro-hole machining Electrical discharge machining Spinning Iron Stainless Aluminum alloy Copper alloy Titanium alloy Nickel alloy Turning machining(plastic) Casting Honing machining Titanium Urethane Ultra-thin High precision |

| Mass production | Plastic | PMMA (polymethyl methacrylate) Engineering plastic PEEK (polyetheretherketone) Thermoset resin GFRP (glass fiber reinforced plastic) |

| Mass production | Grinding processing | Plane grinding Cylindrical grinding |

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Chromium (barrel) Zinc (barrel) Chromate (general) Nickel (rack) Chromium (rack) Zinc (rack) Alumite (anode oxidation) Acid pickling Aldine treatment (aluminum chromate) Parkerizing (phosphate film) Electroless nickel (barrel) Electroless nickel (rack) Chemical conversion coating Baking (hydrogen embrittling) Trivalent Chromate (barrel plating) Iron Copper Brass Aluminum Stainless steel Hard chromium (rack) Titanium Degreasing Black oxide finish Colored alumite Hard alumite Unichromate (white) Black chromate (black/green) Colored chromate (multi-color) Nickel (hoop) Electroless nickel (large) Hard chrome (barrel) Hard chrome (large) Hard alumite (large) |

| Surface treatment | Cleaning | Ultrasonic cleaning |

| Surface treatment | Coating | Air-spray coating Powder coating Electrodeposition coating Melamine coating Urethane coating Acrylic coating |

| Surface treatment | Polishing/Lapping | Electropolishing Chemical polishing Tool polishing Buffing Mirror polishing |

| Surface treatment | Printing and others | NC engraving Silk screen printing |

| Surface treatment | Lap polishing | Lap polishing |

| Surface treatment | Heat treatment | Normalizing Vacuum normalizing Annealing Full annealing Stress relief annealing (SR treatment) Straightening annealing Vacuum annealing Quenching Salt bath quenching Vacuum quenching Austempering High frequency quenching Solution heat treatment Sub-zero treatment Carburized quenching Salt bath soft nitriding (tufftriding) Nitridation Gas nitrocarburizing |

| Surface treatment | Barrel polishing | Barrel finishing (vibration) Barrel finishing (rotation) Barrel finishing (centrifugal) |

| Surface treatment | Other surface treatment | Spraying Teflon coating Shot peening/WPC Buffing Shot blast Sound blast Glass beads blast Etching (surface treatment) DLC coating Deburring |

| Assembly/Inspection | Assembly | Precision equipment assembly Office equipment assembly Industrial machinery assembly |

| Assembly/Inspection | Inspection | Measuring |

| Parts manufacturing | Machinery part | Valve manufacturing Vacuum components manufacturing Connection parts manufacturing Shaft and roller manufacturing pipe manufacturing |

| Product manufacturing | Production property | Machine tool manufacturing Electrical machinery and apparatus manufacturing Energy-saving equipment/Automatic instrument manufacturing Carrier machine manufacturing Measurement/testing devices manufacturing Food industry machinery manufacturing Fluid equipment manufacturing |

| Product manufacturing | Plant equipment manufacturing | Marine vessel equipment manufacturing |

| Product manufacturing | Others | Transportation equipment manufacturing |