- Telephone number: +81-584-89-6598

- FAX: +81-584-89-1186

- Website

- Basic Info

- Equipment

- Technology & Products

- Movie

- EMIDASBLOG

- Map / HQ

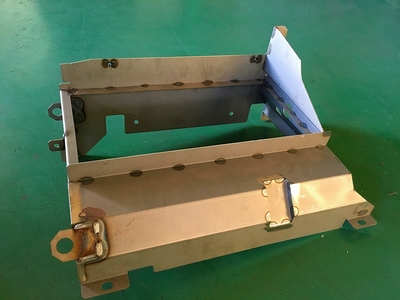

We can design and manufacture molds, ZAS molds, and prototypes using 3D data. We specialize in 3D-printed automotive press parts, high-mix, low-volume mass manufacturing for large construction machinery manufacturers, and thin sheet metal processing.

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Laser and turret punch press processing ( Development and production of prototype/Small-scale production / Blank cutting ) |

|---|---|

|

|

Chassis manufacturing( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|

|

Simple mold, prototype mold( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Bending( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Welding( Development and production of prototype/Small-scale production / Prototype processing ) |

|

|

Precision sheet metal machining( Development and production of prototype/Small-scale production / Sheet-metal processing ) |

|

|

Machining (vertical)( Development and production of prototype/Small-scale production / NC machining ) |

Icon

Company info

| Company name | Hayano Kenko Co.,ltd. | Website URL | https://www.hayanokenko.co.jp/ |

|---|---|---|---|

| Street address |

Ogaki-shi Gifu Japan

[See map] |

Person in charge | Fumihito Hayano |

| Telephone number | +81-584-89-6598 | Fax number | +81-584-89-1186 |

| Capital | 5,000,000 JPY | Employees | 37 |

| Annual sales | 450,000,000 JPY | EMIDAS Member Number | 5681 |

| Type of manufacturing | Machine tools / Transportation equipment / Office appliances | ||

| Main 3 products |

|

||

PR message

We design and manufacture molds/ZAS molds, prototypes from 3D data.

We handle 3D CAD, machining, hydraulic press processing, and 3D laser processing in-house.

We specialize in:

① processing automobile press parts from 3D data

② high-mix, low-volume mass production processing for major construction equipment manufacturers

③ thin sheet metal processing mainly using NCT, laser, and NC brakes

④ steel furniture, office product panels, door units

■CAD

DXF, IGES, STP, PARASOLID intermediate file support

Compatible 3D CAD/CAM:

Sheetworks, SolidWorks Premium, Metacam, CADMEISTER, INVENTER, AP100, Illustrator

■Bending

4×8 size, iron/SUS: 0.5 to 9mm, aluminum: up to 6mm, dimensions ±0.1mm, copper and brass from 0.3mm.

Workpieces with short flange heights or short steps.

We can bend difficult-to-process materials by constructing original molds made in-house using our acquired know-how.

■Turret punch press (compound) processing

Cutting the outside perimeter and drilling tiny diameter holes are integrated into one operation using a multi-tasking machine (Amada LC2512C1AJ), adding to cost savings.

We can respond to short-term delivery products by employing automatic pallet changers that work 24 hours a day.

We utilize our specialist deburring equipment "Metal-Este" to stabilize quality and produce high-quality goods with no scratches or burrs.

■2D/3D laser processing

We have two 3D laser processing machines and one multi-tasking fiber laser cutting machine to perform various types of forming and tapping at the same time.

We offer cost savings by implementing a 24-hour unmanned operation with a 2-shelf loading/unloading standard and a take-out device.

The 3D laser processing machine achieves high-precision processing of 3D products such as various pipe materials, drawn products, and pressed products by using 5-axis control.

We handle cutting in 5x10 sizes and irregularly shaped items.

■Press processing

We have press machines at 100t and 300t. It is suitable with iron sizes ranging from t0.5 to 12mm. We produce 100 to 200 pieces every month.

■Welding/assembly

We have 3 robot welding machines, 10 semi-automatic welding machines, and 6 TIG welding machines.

Even for stainless steel and aluminum, our skilled welders can create beautiful bead finishes.

The rotating table enables for welding at any angle, allowing for more effective welding of workpieces of various forms.

■Machining/Jig production

Using a gate-type machining center x2000 x y1000 x z500 and wire cutting, we can process prototype molds, design and manufacture various jigs and tools.

We provide "+α service", such as additional machining to sheet metal products and conversion of manufacturing methods for difficult to process product shapes with sheet metal processing.

■Materials we handle

Pickling SPHC/Polished SPCC with plate thickness 0.5 to 6.0mm,

Rolled steel plate SS400 (SS41) with plate thickness 2.3 to 12.0/19.0/25.0 and various flat bars,

Carbon steel (JIS G 4051), S45C, S50C,

Alloy tool steel, die steel SKD3,SKD61,SKD11,SKS3,

Stainless steel /SUS303 /SUS304 /SUS316 / SUS430 / SUS410 Clad steel plate for cutlery,

Pure aluminum A1050, A1100, A1070,

Aluminum alloy A2017 A5005P A5052P A6063,

Alumite steel plate A1100 B2 anodized,

Oxygen-free copper/C1020, brass/C2801,

Various plated steel plates ZAM, SPGZL, SGCC, SECC, bonded or colored steel plates,

Electromagnetic steel plate 35G155/23P90, 35A360/50A400

■Surface treatment

Trivalent chromate, hard chrome/decorative chrome/gold/nickel plating

Black cationic electrodeposition/powder/melamine coating, Teflon processing,

Salt bath nitriding/carbonitriding treatment, quenching, tempering

【Head office】

1-86-2 Tagishima, Ogaki-shi, Gifu Prefecture 503-0965

TEL:+81854-89-6598 FAX:+81584-89-1186

【Yoro Factory】

255-1 Murohara Ogurisu, Yoro-cho, Yoro-gun, Gifu 503-1300

TEL:+81584-33-0382 FAX:+81584-33-0389

【Murohara Factory & Antenna Shop】

294 Murohara Ogurisu, Yoro-cho, Yoro-gun, Gifu 503-1301

TEL:+81584-84-7460 FAX:+81584-84-7461

Most recent update:2025-04-16

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Drawing metal press die designing Transfer press die designing General metal press die 3D modeling (press) |

| Designing | Product and part designing | Office equipment designing |

| Designing | Jig and tool designing | General jig designing Welding jig designing Mass production jig designing |

| Designing | Simulation | 3D modeling Press |

| Material | Steel component distribution | Pickled steel plate Stainless steel Cold-rolled steel plate Electroplated steel plate |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Molybdenum alloy Machining (resin) |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) NC milling Handles 3D processing |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining |

| Development and production of prototype/Small-scale production | Sheet-metal processing | Pipe machining Air-conditioning equipment manufacturing NC set press Precision sheet metal machining Chassis manufacturing Sheet metal protocol manufacturing Bending (over 3.0 m) Angle machining Deburring Coating Bending (hydraulic) Thin wall (Thickness |

| Development and production of prototype/Small-scale production | Blank cutting | Turret punch press processing Shearing Cutting Laser and turret punch press processing Laser processing (longer than 121.2 m) Shearing (longer than 121.2 m) Corner shearing CO2 laser machining Thin plate (below 6 mm) Thick plate (over 6 mm) Stainless steel Copper/Aluminum Acrylic 3D laser machining Fiber laser processing |

| Development and production of prototype/Small-scale production | Welding/Adhesive bonding | CO2 welding Spot welding TIG welding (argon welding) Arc welding Stud welding Fiber welding |

| Development and production of prototype/Small-scale production | Jig manufacturing | Welding jig manufacturing Mass production jig manufacturing |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Welding Bending Small-size prototype manufacturing Chassis prototype manufacturing Prototype/Small-lot molding prototype mold |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Die set machining NC data creation 3D modeling Drawing die Bending die Single press die |

| Mass production | Metal press | Drawing Bending Blanking Iron Stainless steel Aluminum Copper Brass Plated steel plate Thickness Single press (below 80 t) Single press (80 - 200 t) |

| Mass production | Mechanical processing | Machining NC turning machining |

| Mass production | Sheet-metal processing | Sheet metal prototype manufacturing Angle processing Bender processing (flood control) Thin (t0.5 or less) / Small sheet metal processing Bending process |

| Mass production | Blank cutting | Laser marking Turret punch punching Shirring Laser and turret punch punching CO2 laser processing Fiber laser processing Thin plate 6 mm or less Thick plate 6 mm or more stainless 3D laser |

| Mass production | Welding / welding | CO2 welding Fiber welding Spot welding TIG welding (argon welding) Arc welding Stud welding |

| Assembly/Inspection | Assembly | Auto parts assembly Construction component assembly Industrial machinery assembly |

| Product manufacturing | Household commodity | Outdoor leisure product manufacturing |

| Product manufacturing | Furniture/Interior | Cabinetmaking Interior manufacturing |

| Product manufacturing | Watch/Glasses/Accessory/Jewelry | Earring manufacturing |