Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Chromium (rack)( Surface treatment / Plating/Chemical conversion treatment ) |

|---|---|

|

|

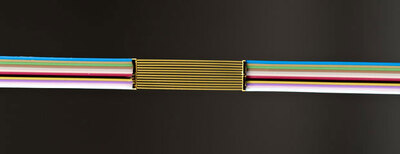

Gold/Silver plating( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Electroless nickel (rack)( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Electroless nickel (barrel)( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Aluminum( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Zinc die-cast( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Stainless steel( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Brass( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Iron( Surface treatment / Plating/Chemical conversion treatment ) |

|

|

Tin (barrel)( Surface treatment / Plating/Chemical conversion treatment ) |

Icon

Company info

| Company name | Hikifune Co., Ltd. | Website URL | |

|---|---|---|---|

| Street address |

Katsushika Tokyo Japan

[See map] |

Person in charge | HikifuneGyoumu |

| Telephone number | +81-3-3696-1981 | Fax number | +81-3-3696-4511 |

| Capital | 24,000,000 JPY | Employees | 125 |

| Annual sales | 1,800,000,000 JPY | EMIDAS Member Number | 45852 |

| Type of manufacturing | Telecommunication equipment / Electronic parts / Electrical component for transportation equipment | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

We want to express Japanese sensibilty and delicacy with "Made in Japan, Made in Tokyo, Made in Katsushika", and spread it to the whole world. We call it Hikifune brand. For this reason, Hikifune strives to research and develop all types of plating technology, and conducts collaborative R&D with companies and universities.

The plating reaction must be scientifically controlled by an invisible mechanism. We are constantly working on technological development that creates new value. With the cutting-edge plating technology we have cultivated, we always strive to manufacture high quality products by making full use of a wide variety of plating specifications and plating processes in order to respond to various customers and needs.

In collaboration with our Engineering Department and Quality Assurance Department on each site, no matter how difficult the request we will find out "the possible method" and produce it.

If you are having trouble with plating, or if you are looking for a plating company, please feel free to contact us.

Plating specialists are waiting for you.

Most recent update:2024-10-28

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Surface treatment | Plating/Chemical conversion treatment | Nickel (barrel) Tin (barrel) Solder (barrel) Copper (barrel) Chromium (barrel) Chromate (general) Rhodium Electroless copper (barrel) Nickel (rack) Copper (rack) Gold/Silver plating Chromium (rack) Black chromium (rack) Nickel chromium (rack) Acid pickling Electroless nickel (barrel) Electroless nickel (rack) Electrocasting Chemical conversion coating Baking (hydrogen embrittling) Iron Copper Brass Zinc die-cast Aluminum Stainless steel Other anti-rust treatments Magnesium Degreasing |

Hikifune Co., Ltd.

Hikifune Co., Ltd.