- Telephone number: +81-299-45-7155

- FAX: +81-299-45-7157

- Website

Products, Expertise & Unique Technical Info

|

Manufacturing category info

|

|

Progressive die( Die manufacturing / Press die ) |

|---|---|

|

|

Thickness: 0.2 mm - 3.2mm( Mass production / Metal press ) |

|

|

Combined press-joining ( Mass production / Metal press ) |

|

|

Thickness: below 0.2 mm( Mass production / Metal press ) |

|

|

Progressive press (35 - 80 t)( Mass production / Metal press ) |

|

|

Copper( Mass production / Metal press ) |

|

|

Phosphor bronze( Mass production / Metal press ) |

|

|

Brass( Mass production / Metal press ) |

|

|

Stainless steel( Mass production / Metal press ) |

|

|

General metal press die( Designing / Mold designing ) |

Icon

Company info

| Company name | Hashimoto Precision Industry Co., Ltd. | Website URL | http://www.hskcoltd.co.jp/ |

|---|---|---|---|

| Street address |

Kasama-shi Ibaraki Japan

[See map] |

Person in charge | Shunichi Maie |

| Telephone number | +81-299-45-7155 | Fax number | +81-299-45-7157 |

| Capital | 30,000,000 JPY | Employees | 45 |

| Annual sales | Unregister | EMIDAS Member Number | 1302 |

| Type of manufacturing | Home electrical appliances / Telecommunication equipment / Electronic parts | ||

| Main 3 products |

|

||

| Primary clients |

|

||

PR message

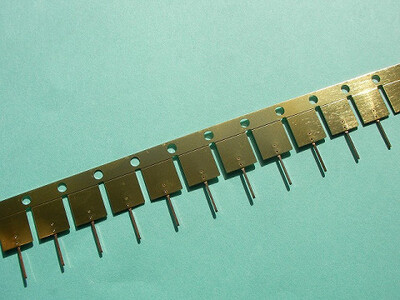

Hashimoto Precision Industry is a manufacturing company that specializes in composite caulking and precision press work that performs all processes from die fabrication to press work. We have achieved processing of various difficult-to-cut materials such as phosphor bronze, beryllium, nickel silver, and stainless steel.

We make use of electric furnaces for heat treatment for beryllium copper and other materials. And depending on the application, on-site heat treatment is also possible for stainless steel and other materials.

Feel free to check out our website for more information and we will gladly support you with quick fixes for stamped parts and the like. We are confident that you will be able to appreciate the distinctive expertise of our business specializing in compound caulking.

We are headquartered in Katsushika-ku, Tokyo, and operate a factory in Kasama City, Ibaraki Prefecture.

Most recent update:2025-02-14

Manufacturing category info

| Large | Medium | Small |

|---|---|---|

| Designing | Mold designing | Progressive die designing (light electrical) Progressive die designing (auto) General metal press die NC data creation (press) |

| Development and production of prototype/Small-scale production | Machining | General-purpose milling General-purpose lathe machining Tapping Machining/Handles small-scale production (order from 1 piece) Iron Stainless steel Aluminum alloy Copper alloy Nickel alloy Brass |

| Development and production of prototype/Small-scale production | NC machining | Machining (vertical) |

| Development and production of prototype/Small-scale production | Electrical discharge machine | Wire electric discharge machining Micro hole machining Electric discharge machining |

| Development and production of prototype/Small-scale production | Grinding processing | Plane grinding Form grinding |

| Development and production of prototype/Small-scale production | Prototype processing | Punching Bending |

| Die manufacturing | Press die | Designing Manufacturing Part processing Plate machining Die set machining NC data creation Bending die Blanking die Progressive die Single press die Below 60 t Compound die |

| Die manufacturing | Spring mold | Designing Manufacturing Spring die part processing Leaf spring die |

| Mass production | Metal press | Bending Blanking Iron Stainless steel Aluminum Copper Brass Phosphor bronze Titanium Plated steel plate Stainless steel material for spring Nickel Thickness Thickness Combined press-joining Beryllium copper Progressive press (35 - 80 t) Progressive press (80 - 200 t) |

| Surface treatment | Cleaning | Hydrocarbon cleaning |

| Assembly/Inspection | Assembly | Construction component assembly |

| Assembly/Inspection | Inspection | Metal press |

| Parts manufacturing | Spring | Thin leaf spring Terminal spring Leaf spring Carbon steel Stainless steel Copper alloy |

![Replacing Machining with Press Processing – [Thick Plate Pressing]](/temp/400_300_a54c156afbb8b515ad34a4730a1736354678a4e5.jpg)

![Replacing Machining with Press Processing – [Thick Plate Pressing]](/temp/110_70_a54c156afbb8b515ad34a4730a1736354678a4e5.jpg)