81-90 / 22744 hits

We can do direct printing on round molded products manufactured by our company using special inkjet printer. As long as you have the data, we can print without the plate (start from 1 line). Cylindrical shape φ10 to 100φ Length 10mm to 330mm Flat surface 300 mm x 300 mm

| Main 3 products | Pharmaceutical containers, quasi-drug containers, cosmetic containers, mini tube containers, testing reagent containers, testing reagent parts Caps, bottles, tubes, syringes, transparent cases Laminated tube parts, parts for dentistry, inspection containers |

|---|---|

| Type of manufacturing | Medical equipment Stationery products Leisure goods |

| Recommended manufacturing category |

1:Mass production - Plastic - Blow molding 2:Mass production - Plastic - Injection molding 3:Surface treatment - Printing and others - Silk (handles curved surface) 4:Surface treatment - Printing and others - Silk screen printing 5:Surface treatment - Printing and others - Hot stamping (gold embossing) 6:Mass production - Plastic - Thin wall molding 7:Assembly/Inspection - Inspection - Plastic 8:Surface treatment - Printing and others - Pad printing 9:Surface treatment - Printing and others - Direct printing 10:Development and production of prototype/Small-scale production - Prototype processing - Prototype/Small-lot molding |

Ceramics Processing, Component Arrangement, and Assembly! CE-RISE's manufacturing service Ceramic prototypes and ceramic products can be made from a single piece in as little as 5 days without molds (custom-made products are also available). (We can also handle custom-made products.) We can handle everything from small quantities to mass production. From drawing to quotation in 3 hours. Our skilled engineers manufacture ceramic parts with high hardness, heat resistance, corrosion resistance, and electrical insulation to support your manufacturing. Materials Combination of ceramics, resin, metal, glass, etc. Industries and Applications Medical equipment Machining】 Design + Ordering + Machining + Assembly Design + Ordering + Processing + Assembly Features CE-RISE can solve your current problems! Ceramics processing, parts arrangement, and assembly are available! One-stop service for all processes up to assembly! We deliver careful and accurate products with pride of Made in Japan. If you have any questions or concerns, please feel free to contact us. https://ceramic.co.jp/ Click here for inquiry form ↘↘ (click for details button 👇🏻) 📞TEL: 03-3755-0660

| Main 3 products | Ceramic Products Mass Production, prototype, manufacturing |

|---|---|

| Type of manufacturing | Machine tools Medical equipment Lighting equipment |

| Recommended manufacturing category |

1:Mass production - Mechanical processing - Machining 2:Mass production - Grinding processing - Plane grinding 3:Mass production - Grinding processing - Cylindrical grinding 4:Development and production of prototype/Small-scale production - NC machining - Handles 3D processing 5:Die manufacturing - Powder metallurgy mold - Metal die 6:Mass production - Mechanical processing - NC turning machining 7:Surface treatment - Other surface treatment - Shot blast 8:Mass production - Mechanical processing - NC milling machining 9:Development and production of prototype/Small-scale production - Jig manufacturing - Jig and tool manufacturing 10:Development and production of prototype/Small-scale production - Machining - Ceramic |

A vacuum cleaner that meets Japan's high-quality standards while achieving cost reduction through Indian manufacture. Combines vapor cleaning, endless shower cleaning, and high-efficiency regeneration devices to provide high-quality cleaning at low cost. This vacuum cleaner is an innovative product made in India, capable of meeting the high-quality standards of Japan while allowing for reduced manufacturing costs. By adopting vapor cleaning, endless shower cleaning, and high-efficiency regeneration devices, it improves cleaning quality while simultaneously reducing the environmental burden through the recycling of cleaning fluids. A simple structural design inside the cleaning chamber reduces troubles and cuts down on maintenance effort and costs. Features High Quality and Low Cost: Offers performance that meets Japanese quality standards at a low price due to Indian manufacture. High-Efficiency Cleaning System: Achieves thorough cleaning through the combination of vapor cleaning and endless shower cleaning. Cleaning Fluid Regeneration Device: Regenerates 70L of cleaning fluid within the cycle, significantly reducing the discharge of waste fluids. Simple Structure: A design without conveyance mechanisms inside the cleaning chamber reduces the rate of malfunctions. Specifications Cleaning Method: Vapor cleaning, endless shower cleaning Regeneration Device: High-efficiency device for the recycling of cleaning fluids Structure: Simplified structure inside the cleaning chamber Cleaning Fluid Processing Capacity: Regeneration of 70L of cleaning fluid within the cycle This vacuum cleaner provides a sustainable cleaning solution that maintains high cleaning quality while reducing both environmental impact and operational costs. It is expected to be used across a wide range of applications, from manufacturing to the medical field.

| Main 3 products | Heat treatment surface treatment (carbur Quenching and tempering Gas soft nitriding |

|---|---|

| Type of manufacturing | Not selected Transportation equipment |

| Recommended manufacturing category |

| Type of manufacturing | Industrial machinery Transportation equipment Electrical component for transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Parts manufacturing - Bolt/Screw/Nut - Screw manufacturing |

This product is for bundling various kinds of paper together. This can handle from a single sheet of paper to papers folded in 2,3, ....plurally folded paper. This is also equipped with Double-Feeding Detection System. In Japan, this is generally used for auto-insertion of flyers, pamphlets etc. into daily newspaper. This products is highly expected to have further possible usages in your country. Genesis collator is the labor-saving machinery which combines different varieties of papers to one sheaf. In Japan, we use Genesis collator to gather vehicles known as “Chirashi (flyer)” into a set. Since a copier has an ability to sort papers, it can’t cope with flyers because they come in with different paper qualities and unique ways of folding. The machine proceeds and collates any type of paper in the same way as long as it meets the specific requirement.That is our proud product “Genesis collator". Because Genesis collator has to gather flyers with a various qualities of papers into a single set, it is equipped with a double feeding detection system, which thought to be difficult to design. Our an unique double feeding detection system will prevent from future double feedings which may occur during the state in which papers clung easily due to paper quality, ink, moisture, or static electricity. In addition, by utilizing “KNS sheet”, which is registered utility model an optional part for the collator, enables the machine to proceed and gather easily clung papers without any difficulties. Genesis collator also detects “missed inserts” and "paper jams" automatically, and it displays the errors clearly on a tablet terminal which prevents a missing page or disarranged pages greatly. Capacity 150papers/min. Paper size Postcard~A3 size / ordinary shelf B5~B3/ folding shelf Paper feeds Diagonally piling up (can be heap up) Dimension mm Height 1,975-1,475 (depend on the model) Width 720 (all models common) Depth while using: 1,322-1,270 (depends on the model) While Storing 992-965 (depends on the model) Weight (kg) 430-270 (The following are Japanese specifications'' reference data) Motor rating 750W Power supply AC100V 50/60Hz Consumption electricity 700W - 1,100W (depends on the model) Operating temperature -10℃ ~+50℃ Preservation temperature -20 ℃~+60 ℃s Registered patent ■Patent: The sheet feeding apparatus for the paper collator The pin wheel No: 3382705 ■Patent: Newspaper inserts paper collator Quantity display dropout paper NO:4187245 ■utility models : Separation force adjustment tool of the the paper feeder Rubber chip hidden NO:3126986 Patent pending ■special permission Patent ApplicationNO: 2010-284161 collator The Double feed detection by Ultrasonic Others

| Main 3 products | Machining, NC lathe |

|---|---|

| Type of manufacturing | Industrial machinery Construction material Transportation equipment |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 2:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Robot welding 3:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 4:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 5:Designing - Industrial equipment designing - Industrial machinery designing 6:Designing - Industrial equipment designing - Energy-saving machinery designing 7:Assembly/Inspection - Assembly - Industrial machinery assembly 8:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Arc welding 9:Development and production of prototype/Small-scale production - Machining - Keyway milling 10:Designing - Industrial equipment designing - Carrier machine designing |

| Type of manufacturing | Machine tools Industrial machinery Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Blank cutting - YAG laser machining 2:Development and production of prototype/Small-scale production - Blank cutting - CO2 laser machining 3:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - YAG laser machining 4:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 5:Development and production of prototype/Small-scale production - Prototype processing - Welding 6:Mass production - Metal press - Stainless steel 7:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Arc welding 8:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 9:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - CO2 welding 10:Development and production of prototype/Small-scale production - Prototype processing - Bending |

Our wiring boards are an indispensable element in the assembly of electrical control cabinets that require precise operation. The meticulous wiring work is performed by professionals with specialized skills, achieving high reliability to meet the electrical control needs of various industries. These wiring boards are core components ensuring the efficient and safe operation of machinery. ■ Features ・ Wiring boards with quality and precision surpassing industry standards. ・ Reliable electrical control cabinets support stable system operation. ・ Precise work by professionals capable of assembling complex electrical systems.

| Main 3 products | assembling small machines assembling automatic measuring machines manufacturing automotive parts |

|---|---|

| Type of manufacturing | Industrial machinery |

| Recommended manufacturing category |

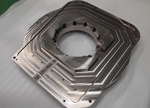

"This is a base plate for high-precision machine tools. The material is SUS303. We annealed the plate material of SUS303 and processed it by turning process and machining. This is a product that takes time to process due to its high precision and processing, but we were able to produce it well by our integrated production, which is our strength. The machining accuracy is 0.01 mm for parallelism, 0.01 mm for concentricity, and 0.02 for hole position accuracy. 【Processing equipment】 ・Vertical NC lathe Okuma V60-R ・Vertical machining center Makino V77L Please feel free to contact us for any product. Industry: for machine tools Product name: base plate Material: SUS303 (annealed) Size: 400 x 400 x 50 Accuracy: parallelism 0.01 mm, concentricity 0.01 mm, hole position accuracy 0.02 Lot: 2-4 pieces Processing days: 1 month <<< Abundant equipment that enables integrated production >>> We have abundant equipment such as large 5-sided processing machines with a maximum of 6,000 x 1,800, 5-axis processing machines, NC combined lathes, turning centers, flat surfaces, cylinders, various grinding machines, gun drill machines, etc. ※We will cooperate with subcontract factories for equipment we do not have such as wire cuts, to enable integrated production. Glory is a professional of ""large scale"", ""casting"", and ""complex shape processing"". We can handle a wide range of products from iron castings such as FC / FCD to aluminum castings such as AC. We specialize in large-scale processing up to 6000mm x 1800mm. Lot from 1 piece, and various processing is possible. Feel free to contact for a quotation to Komori (sales person). GLORY CO.,LTD. 8587, Minami Minowa-mura, Kamiina-gun, Nagano Prefecture, 399-4511 TEL: +81-265-73-9324 FAX: +81-265-73-2865 Person in charge: Ohara"

| Main 3 products | Ultra-precision metal processing Large casting parts processing Aluminum product processing (including AC) |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 3:Development and production of prototype/Small-scale production - NC machining - NC milling 4:Development and production of prototype/Small-scale production - NC machining - NC vertical lathe 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 7:Development and production of prototype/Small-scale production - Grinding processing - NC cylindrical grinding 8:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 9:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 10:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing |

We possess many vertical molding machines, such as 56 machines in Japan and 13 ones in Indonesia, and we have been supplying insert molding products to a variety of industries.

| Main 3 products | Electrical part Module case Wiring board. |

|---|---|

| Type of manufacturing | Industrial machinery Electronic parts Electrical component for transportation equipment |

| Recommended manufacturing category |

1:Parts manufacturing - Electric board and electronic part - Large current board 2:Designing - Mold designing - Injection molding die 3:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 4:Die manufacturing - Plastic mold - Insert molding die 5:Mass production - Plastic - PPS (polyphenylene sulfide) 6:Mass production - Plastic - PBT (polybutylene terephthalate) 7:Surface treatment - Plating/Chemical conversion treatment - Copper 8:Assembly/Inspection - Inspection - Metal press 9:Die manufacturing - Press die - Part processing 10:Mass production - Metal press - Brass |

Balancing precision and production efficiency with next-generation forging technology. ■ Features This forging machine enhances the microstructure of materials through hot forging, improving product strength and durability. Its high-speed horizontal design significantly boosts production efficiency and contributes to cost reduction. Moreover, equipped with a precise control system, it can forge parts with complex shapes accurately. ■ Specifications - Consistent quality assurance through advanced temperature management functions - Efficient production lines established by integrating multiple forging steps - Work efficiency optimized with automated material supply and retrieval systems - Environmentally friendly, energy-saving design By adopting this forging machine, companies can achieve improved product quality, enhanced production efficiency, and cost reduction. For more details, please download the PDF or feel free to contact us.

| Main 3 products | die forgings Support for companies expanding into TH |

|---|---|

| Type of manufacturing | Industrial machinery |

| Recommended manufacturing category |

81-90 / 22744 hits