71-80 / 14565 hits

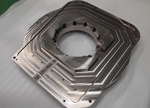

"This is a base plate for high-precision machine tools. The material is SUS303. We annealed the plate material of SUS303 and processed it by turning process and machining. This is a product that takes time to process due to its high precision and processing, but we were able to produce it well by our integrated production, which is our strength. The machining accuracy is 0.01 mm for parallelism, 0.01 mm for concentricity, and 0.02 for hole position accuracy. 【Processing equipment】 ・Vertical NC lathe Okuma V60-R ・Vertical machining center Makino V77L Please feel free to contact us for any product. Industry: for machine tools Product name: base plate Material: SUS303 (annealed) Size: 400 x 400 x 50 Accuracy: parallelism 0.01 mm, concentricity 0.01 mm, hole position accuracy 0.02 Lot: 2-4 pieces Processing days: 1 month <<< Abundant equipment that enables integrated production >>> We have abundant equipment such as large 5-sided processing machines with a maximum of 6,000 x 1,800, 5-axis processing machines, NC combined lathes, turning centers, flat surfaces, cylinders, various grinding machines, gun drill machines, etc. ※We will cooperate with subcontract factories for equipment we do not have such as wire cuts, to enable integrated production. Glory is a professional of ""large scale"", ""casting"", and ""complex shape processing"". We can handle a wide range of products from iron castings such as FC / FCD to aluminum castings such as AC. We specialize in large-scale processing up to 6000mm x 1800mm. Lot from 1 piece, and various processing is possible. Feel free to contact for a quotation to Komori (sales person). GLORY CO.,LTD. 8587, Minami Minowa-mura, Kamiina-gun, Nagano Prefecture, 399-4511 TEL: +81-265-73-9324 FAX: +81-265-73-2865 Person in charge: Ohara"

| Main 3 products | Ultra-precision metal processing Large casting parts processing Aluminum product processing (including AC) |

|---|---|

| Type of manufacturing | Jigs and tools Machine tools Industrial machinery |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - NC machining - Machining (vertical) 2:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 3:Development and production of prototype/Small-scale production - NC machining - NC milling 4:Development and production of prototype/Small-scale production - NC machining - NC vertical lathe 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Grinding processing - NC plane grinding 7:Development and production of prototype/Small-scale production - Grinding processing - NC cylindrical grinding 8:Development and production of prototype/Small-scale production - Sheet-metal processing - Can manufacturing 9:Development and production of prototype/Small-scale production - NC machining - Combined lathe machining 10:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing |

We possess many vertical molding machines, such as 56 machines in Japan and 13 ones in Indonesia, and we have been supplying insert molding products to a variety of industries.

| Main 3 products | Electrical part Module case Wiring board. |

|---|---|

| Type of manufacturing | Industrial machinery Electronic parts Electrical component for transportation equipment |

| Recommended manufacturing category |

1:Parts manufacturing - Electric board and electronic part - Large current board 2:Designing - Mold designing - Injection molding die 3:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 4:Die manufacturing - Plastic mold - Insert molding die 5:Mass production - Plastic - PPS (polyphenylene sulfide) 6:Mass production - Plastic - PBT (polybutylene terephthalate) 7:Surface treatment - Plating/Chemical conversion treatment - Copper 8:Assembly/Inspection - Inspection - Metal press 9:Die manufacturing - Press die - Part processing 10:Mass production - Metal press - Brass |

[Molded fluorocarbon rubber (FKM), semiconductor manufacturing, bonded gate seal] [Material] ・ Stainless steel (SUS316 / SUS304) + high-performance fluorocarbon rubber (FKM) ・ Aluminum alloy (A5052 / A6061) + High-performance fluorocarbon rubber (FKM) [Industry / Usage] ・ Semiconductor manufacturing equipment related industry [Size] ・ 200 mm type ・ 300 mm type [Processing] ・ Machining processing ・ Press molding ・ Surface treatment (selected according to required specifications) [Feature] This bonded gate seal is a product that can improve the performance of the opening / closing door used in the vacuum chamber of the semiconductor process and also can extend its lifespan. Feature: ◆ Replacement makes it easier to replace parts ◆ Free rubber compounding is possible ◆ Seal design can be changed We have an integrated production system from rubber compound development to mold design, manufacturing, inspection, cleaning, and shipping, so we can cooperate regarding delivery time and cost. If you are interested, please contact us. U・M・I Co., Ltd. 1-6 Hayashi Takaguro, Kumiyama-cho, Kuse-gun, Kyoto 613-0033 TEL. +81-774-44-5151 FAX. +81-774-44-5172 Person in charge: Okamoto

| Main 3 products | Resin, aluminum, SUS, special rubber products for semiconductor / liquid crystal manufacturing equipment Resin, aluminum, SUS, special rubber products for medical and pharmaceutical equipment Resin, aluminum, SUS, special rubber products for electronic device manufacturing equipment |

|---|---|

| Type of manufacturing | Home electrical appliances Office automation equipment Electronic parts |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Machining - Handles microfabrication 2:Mass production - Plastic - PI (polyimide) 3:Development and production of prototype/Small-scale production - Machining - Machining (resin) 4:Development and production of prototype/Small-scale production - NC machining - 5-face/5-axis machining 5:Development and production of prototype/Small-scale production - NC machining - NC lathe machining 6:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing 7:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 8:Development and production of prototype/Small-scale production - Machining - Stainless steel 9:Development and production of prototype/Small-scale production - Machining - Titanium alloy 10:Mass production - Rubber - Vulcanization adhesion |

| Type of manufacturing | Machine tools Industrial machinery Construction material |

|---|---|

| Recommended manufacturing category |

1:Mass production - Casting - Ductile cast iron 2:Mass production - Casting - Cast-iron 3:Mass production - Casting - Over 500 g and less than 5 kg 4:Mass production - Casting - 5 kg and over 5:Die manufacturing - Casting die - 3D modeling 6:Development and production of prototype/Small-scale production - Casting - Ductile cast iron 7:Development and production of prototype/Small-scale production - Casting - cast iron 8:Development and production of prototype/Small-scale production - Casting - 500g-5kg 9:Development and production of prototype/Small-scale production - Casting - 5kg or more 10:Development and production of prototype/Small-scale production - Casting - Sand casting |

There are three types of welding methods. -Fusion welding -Pressure welding -Brazing This time, we would like to introduce about copper and copper welding, which is our strength. ● Fusion welding: A method of melting and welding the part to be welded → Arc welding (method of melting and welding materials with high current + gas) Typical example ①MAG welding: CO₂ gas 100% Or argon 80% + CO₂ 20% ②MIG welding: Argon 100% ③TIG welding: Argon 100% <Meaning of each alphabet> M…METAL A…Active (active gas) I…Inert (inert gas) T…Tungsten (electrode) We use direct current of TIG welding to perform copper + copper welding. The base material to be welded is preheated and welded with electricity, but the electricity and heat are dispersed and emitted in all directions of the copper material, making temperature control and speed extremely difficult. For this reason, expert techniques and tricks are important due to current adjustment during welding, gas adjustment called after-flow, etc. are different each time depending on the season, temperature, and copper lot. ● Additional explanation TIG welding of dissimilar materials such as copper and aluminum is not possible. Reason 1: The melting point of copper is 1085℃, and the melting point of aluminum is 660℃. Reason 2: The welding conditions are very different from DC for copper and AC for aluminum. This time, we introduced one of the three types of welding, "fusion welding". The article below introduces "brazing" and TIG welding machines, so please take a look. 75 years of our strength, "brazing", one of the welding methods https://en.nc-net.or.jp/company/91883/product/detail/185141/ Please contact us for copper and aluminum precision parts processing. You may find information on processing technology such as copper bus bars, copper rods and copper precision parts on our website. http://ishigaki-st.com ISHIGAKI SHOUTEN Inc. 1-629 Seko, Moriyama Ward, Nagoya City, Aichi Prefecture 463-0068 TEL 052-793-3080 FAX 052-793-1079 E-mail: info@ishigaki-st.com Person in charge: Sales Department Sodeoka

| Main 3 products | Transformer parts (copper strips, etc) Control panel parts (copper bar, etc) Vehicle parts (connecting conductors) |

|---|---|

| Type of manufacturing | Heavy electric machinery Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Mass production - Metal press - Copper 2:Development and production of prototype/Small-scale production - Machining - Machining/Handles small-scale production (order from 1 piece) 3:Development and production of prototype/Small-scale production - Sheet-metal processing - Sheet metal protocol manufacturing 4:Mass production - Mechanical processing - Machining 5:Development and production of prototype/Small-scale production - Prototype processing - Bending 6:Mass production - Mechanical processing - Complex turning machining 7:Mass production - Mechanical processing - High precision 8:Development and production of prototype/Small-scale production - Blank cutting - Copper/Aluminum 9:Material - Nonferrous metal distribution - Copper and brass products 10:Surface treatment - Plating/Chemical conversion treatment - Copper |

| Type of manufacturing | Machine tools Industrial machinery Kitchen |

|---|---|

| Recommended manufacturing category |

1:Parts manufacturing - Spring - Diameter: less than 0.6 mm 2:Parts manufacturing - Spring - Compression coil spring 3:Parts manufacturing - Spring - Tensil coil spring 4:Parts manufacturing - Spring - Torsion spring 5:Parts manufacturing - Spring - Formed wire spring 6:Parts manufacturing - Spring - Shaped spring 7:Parts manufacturing - Spring - Diameter: 0.6 to 6.0 mm |

| Type of manufacturing | Not selected Jigs and tools Industrial machinery |

|---|---|

| Recommended manufacturing category |

2:Development and production of prototype/Small-scale production - Machining - Simultaneous 5-axis machining 3:Product manufacturing - Production property - Energy-saving equipment/Automatic instrument manufacturing |

| Type of manufacturing | Industrial machinery Telecommunication equipment Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Casting - Gypsum casting 2:Development and production of prototype/Small-scale production - Prototype processing - Prototype/Small-lot molding 3:Die manufacturing - Casting die - Sand casting die 4:Development and production of prototype/Small-scale production - Machining - Aluminum alloy 5:Development and production of prototype/Small-scale production - Machining - Magnesium alloy 6:Designing - Simulation - 3D modeling 7:Development and production of prototype/Small-scale production - Prototype processing - Plaster casting prototype 8:Designing - Data creation (3D scan) - 3D printer 9:Development and production of prototype/Small-scale production - Prototype processing - Simplified/Molding |

"[Product name] Semiconductor manufacturing equipment parts [Material] AC4C-T5 (T6) [Manufacturing method] V process casting [Lot] 10 to 100 pieces [Features] No rough texture to general sand castings, beautiful casting surface and quality stability peculiar to V process are excellent in customer reliability. We have received high trust from several major electronics manufacturers for ""beautiful casting surface"" and ""no mold cavity""."

| Main 3 products | Aluminum casting (mold casting) Aluminum casting (V process casting) Cast aluminum material machining |

|---|---|

| Type of manufacturing | Heavy electric machinery Industrial machinery Electronic parts |

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Casting - Gravity casting 2:Mass production - Casting - Gravity casting 3:Mass production - Casting - Sand casting 4:Development and production of prototype/Small-scale production - Casting - Sand casting 5:Surface treatment - Heat treatment - Solution heat treatment 6:Development and production of prototype/Small-scale production - Casting - 5kg or more 7:Mass production - Casting - 5 kg and over |

| Type of manufacturing | Electronic parts Construction material Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Surface treatment - Plating/Chemical conversion treatment - Electroless nickel (rack) 2:Surface treatment - Plating/Chemical conversion treatment - Nickel chromium (rack) 3:Surface treatment - Plating/Chemical conversion treatment - Zinc (rack) 4:Surface treatment - Plating/Chemical conversion treatment - Alumite (anode oxidation) 5:Surface treatment - Plating/Chemical conversion treatment - Copper (rack) 6:Surface treatment - Plating/Chemical conversion treatment - Black chromium (rack) 7:Surface treatment - Other surface treatment - Coating 8:Surface treatment - Plating/Chemical conversion treatment - Unichromate (white) 9:Surface treatment - Plating/Chemical conversion treatment - Aluminum 10:Surface treatment - Plating/Chemical conversion treatment - Stainless steel |

71-80 / 14565 hits