1-10 / 22747 hits

| Type of manufacturing | Industrial machinery Transportation equipment |

|---|---|

| Recommended manufacturing category |

1:Mass production - Mechanical processing - NC turning machining 2:Mass production - Mechanical processing - Machining 3:Development and production of prototype/Small-scale production - Machining - Casting 4:Mass production - Mechanical processing - Ultra-thin 5:Mass production - Mechanical processing - High precision 6:Mass production - Mechanical processing - Iron |

The powder transport system developed by Belief Engineering Technology (Wuxi) Co., Ltd. uses advanced automatic control technology to smoothly meter and transport powder from stock tanks, revolutionizing the problem of clogging and clumping in the industry. will be solved. Developed by Belief Engineering Technology (Wuxi) Co., Ltd., this powder transport system provides an advanced solution to common challenges in powder handling: clumps and jams. Masu. In particular, we focus on measuring powder from stock tanks and use precise automatic control technology to achieve stable transportation performance. Features Advanced automatic control technology effectively prevents powder clumping and clogging. The process from powder measurement to transportation is automated, making work more efficient. It can be flexibly adjusted according to powder properties and environmental conditions, and can be used in a wide range of applications. The system is easy to maintain and manage, and stable operation can be expected over a long period of time. specification It is equipped with precise weighing and transportation functions centered on an automatic control system. It can be transported directly from a stock tank and can be transported according to the properties of the powder. It can be customized according to user needs and can meet the demands of various industries. Belief Engineering Technology (Wuxi) Co., Ltd.'s powder transportation system solves problems in powder handling and contributes to improving productivity.

| Main 3 products | Mobile containers for on-site use Powder conveying system |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

We sales Mitsubishi Materials's cutting tool for manufacture.

| Main 3 products | Sales cutting tool |

|---|---|

| Type of manufacturing | Jigs and tools |

| Recommended manufacturing category |

| Main 3 products | Iron and Non-Ferrous Metal Plant Burners and Combustion Control Equipment Materials Heat Treatment Furnace |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

Thouzer is a robot that safely and efficiently transports heavy objects, making the most of even in tight spaces. The collaborative transport robot Thouzer can transport heavy objects weighing up to 120 kg, greatly reducing the burden on workers. Designed to function in narrow passageways and rainy conditions, it can also be used outdoors. It is easy to operate and you can start using it in the field right away. Features It follows the worker and supports the transportation of heavy loads. The maximum load capacity is 120kg, allowing you to carry heavy items with ease. The vehicle body is compact and does not require a minimum aisle width of 80cm when driving straight. A wide range laser sensor automatically avoids obstacles. Equipped with a high-capacity battery, it can operate continuously for approximately 20km. specification Dimensions: width 600mm x length 950mm x height 455mm Loading platform: width 600mm x length 750mm x thickness 60mm (aluminum structure) Maximum speed: 7.5km/h when following Battery: 12V34Ah x 2 (continuous operation 20km) Operation: joystick or auto-following mode Purpose Thouzer is especially recommended for use in manufacturing plants and distribution warehouses, where it performs well in narrow aisles and busy environments. Its adaptability can also be utilized in medical facilities, exhibition halls, etc. For more information about Thouzer, please download the PDF or feel free to contact us.

| Main 3 products | Aluminum extrusion FA Solution Providing control and drive equipment |

|---|---|

| Type of manufacturing | Not selected |

| Recommended manufacturing category |

"Proposal of camera cleaning unit for automobiles Small DC pump (micropump mechanism / structural design) / housing molding / assembly ① ADAS driving support & security Back monitor parts for driving support system ② Small DC pumps (micro pumps) are proposed from the mechanical and structural design and produced at our factory. ③ Some of the resin molded products, (including housing molding) are produced at our factory. Features High flow rate, high pressure, optimal unit design (1) Achieve cleaning power with high flow rate and high pressure. (2) Further noise reducing and vibration by designing the mechanism and structure of the unit. Application Automobile parts, cleaning pump unit for back monitor For cleaning camera lenses Improve monitor visibility * We will respond promptly to inquiries □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□ TADA PLASTIC INDUSTRIAL CO.,LTD. 2-12-8, Tsudo, Fujiidera Shi, Osaka, Japan 583-0037 TEL:0081-729540981 http://www.tadapla.co.jp Ideas and technology that lead to innovation Fusion technology Injection molding Urethane foam Micro pump Precision rubber molding □□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□□

| Main 3 products | Compact DC pump Injection molding Urethane foam |

|---|---|

| Type of manufacturing | Transportation equipment Electronic parts Medical equipment |

| Recommended manufacturing category |

1:Mass production - Plastic - PU (polyurethane) 2:Mass production - Plastic - Expansion molding 3:Mass production - Plastic - GFRP (glass fiber reinforced plastic) 4:Mass production - Plastic - Gas injection 5:Mass production - Plastic - Injection molding 6:Mass production - Plastic - 60 - 300 t 7:Mass production - Plastic - PPS (polyphenylene sulfide) 8:Mass production - Plastic - CFRP (carbon fiber reinforced plastic) 9:Mass production - Plastic - PBT (polybutylene terephthalate) 10:Mass production - Plastic - Elastomer |

[Prototypes] Quick delivery without the use of molds! [Material] Iron Galvanized steel plate SECC [Size] t=2.0mm Product size: 360.5 x 46 x 69 [Lot] 1 to 50 [Accuracy] ±0.1 to ±0.5 [Processing method] Programming → Laser processing → Finishing → Countersink burring → M4 tapping → M3 tapping → Hemming (seam) → Bending [Industry/Application] Electrical parts Bracket used for part of the upper housing [Feature] This prototype product is utilized in electrical-related products. We have experience in handling prototypes for sheet metal processing from one piece. The outside perimeter of this product is finished after laser processing, and bending is performed after burring and tapping. As shown in the photo, there are several bends and the U-shaped tip is bent further inward, thus bending it into the product shape will be impossible if the order of bending is incorrect. We delivered this prototype within a week after receiving the order. We are pleased to discuss with you about your needs. Starting with a single prototype, please do not hesitate to contact us if you are experiencing any difficulties with prototypes, presses, or sheet metal. Zaou Seisakusho Co., Ltd. is a parts manufacturer that specializes in precision sheet metal processing by laser processing and press processing with a maximum capacity of 300 tons. In addition, in order to satisfy our customers' QCD, the biggest feature is that we are doing one-stop from mold making to press work in-house. As a post-press process, we comprehensively support caulking, tapping, spotting, welding, assembly, etc. We are currently working on improving our sales support. ◇Contact us◇ 225 Osawa Sengoku, Kaminoyama-shi, Yamagata 999-3122 TEL: +8123-672-2237 FAX: +8123-672-2418 https://www.zao-press.jp/ E-mail: y-suzuki@zao-press.co.jp Please contact Sales Department (PIC:Suzuki)

| Main 3 products | Automotive parts Copying machine, OA parts related Electrical parts |

|---|---|

| Type of manufacturing | Office automation equipment Transportation equipment Medical equipment |

| Recommended manufacturing category |

1:Mass production - Metal press - Progressive press (80 - 200 t) 2:Designing - Mold designing - Progressive die designing (auto) 3:Designing - Mold designing - Progressive die designing (light electrical) 4:Designing - Mold designing - Drawing metal press die designing 5:Designing - Mold designing - General metal press die 6:Mass production - Metal press - Single press (80 - 200 t) 7:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 8:Development and production of prototype/Small-scale production - Machining - Tapping 9:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - TIG welding (argon welding) 10:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Robot welding |

| Type of manufacturing | Audio-video equipment Telecommunication equipment Medical equipment |

|---|---|

| Recommended manufacturing category |

1:Development and production of prototype/Small-scale production - Sheet-metal processing - Precision sheet metal machining 2:Development and production of prototype/Small-scale production - Prototype processing - Small-size prototype manufacturing 3:Development and production of prototype/Small-scale production - Prototype processing - Chassis prototype manufacturing 4:Mass production - Plastic - Handles small-scale production 5:Development and production of prototype/Small-scale production - Welding/Adhesive bonding - Fiber welding 6:Designing - Data creation (3D scan) - Data creation (3D scan) 7:Designing - Mold designing - 3D modeling (press) 8:Designing - Mold designing - 3D modeling (plastic) 9:Die manufacturing - Press die - 3D modeling 10:Die manufacturing - Press die - Designing |

【Long-established integrated manufacturer of industrial packing and fluororesin gasket since 1907! Ono Corporation (Kobe, Hyogo & Sasebo, Kyushu)】 We are a long-established manufacturer of industrial packing and gaskets for the domestic market since 1907. We continue to strive every day by utilizing the "technology" and "know-how" we have developed during our over 100-year existence. Initially, our company produced gland packing. We currently manufacture a wide range of goods, including integrated production from PTFE (fluororesin) powder raw materials, engineering plastics, rubber, and metal processing. We create and support a wide range of products that are essential to people's lives. ~List of compatible products~ 〇Kobe factory〇 Fluororesin molding, resin processing, engineering plastic processing, gland packing, rubber molding, etc. related page⇒ https://en.nc-net.or.jp/company/74850/product/detail/109513/ 〇Kyushu factory〇 Metal processing, laser processing, sheet metal processing, can manufacturing processing, etc. related page⇒ https://en.nc-net.or.jp/company/74850/product/detail/109416/ 【Whats is OR-PACKING ?】 (Description in Japanese) https://www.nc-net.or.jp/company/74850/product/detail/205319/ 【What is OR Flon ?】 (Description in Japanese) https://www.nc-net.or.jp/company/74850/product/detail/180297 ◆Ono Corporation YouTube◆ Please see our YouTube channel for production process videos and manufacturing related trivia videos here! https://www.youtube.com/channel/UCPdFMm8DVM6g-8g14LkMSBg ※Please click "For more details" on the bottom to see our products and more information about us from our website♪ Ono Corporation Tokyo Sales Office TEL +813-3553-4651 FAX +813-3553-4654 Osaka Sales Office TEL +816-6582-9612 FAX +816-6582-9615 Kobe Sales Office TEL +8178-591-1201 FAX +8178-591-1227 Kyushu Sales Office TEL +81956-30-7331 FAX +81956-30-7320 URL https://www.ohnosha.co.jp/ e-mail info2@ohnosha.co.jp Instagram https://www.instagram.com/ohnosha_packing/ YouTube https://www.youtube.com/channel/UCPdFMm8DVM6g-8g14LkMSBg

| Main 3 products | Molding and Processing of PTFE and Teflon PEEK, Vespel, POM, MC Nylon Resin Processing Gland packing, metal gaskets, rubber O-rings, molded rubber products |

|---|---|

| Type of manufacturing | Heavy electric machinery Industrial machinery Transportation equipment |

| Recommended manufacturing category |

1:Mass production - Plastic - Fluororesin 2:Mass production - Rubber - Packing-related products 3:Mass production - Plastic - Engineering plastic 4:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 5:Mass production - Mechanical processing - Turning machining(plastic) 6:Development and production of prototype/Small-scale production - Machining - Milling (resin) 7:Development and production of prototype/Small-scale production - Machining - Machining (resin) 8:Mass production - Plastic - PEEK (polyetheretherketone) 9:Mass production - Rubber - Fluoro-rubber 10:Mass production - Rubber - NBR |

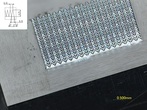

<<Small four-sided pyramids fabricated by Profile grinder>> We made small four-sided pyramids by Profile grinder. In order to realize smart mobility including autonomous driving, various electronic parts related to autonomous driving are required. At our company, we are involved in the design and production of the molds, devices, jigs and tools that are necessary to manufacture these electronic components. Please feel free to contact us when manufacturing electronic parts such as automatic driving. Material : STAVAX (Stainless steel X30Cr13 similar) 52±1 HRC Width of pyramid : 0.1mm Height of pyramid : 0.25mm Tolerance : ±0.002mm If you need a high precision and skall products, please contact us! <For inquiries, please contact here> Headquarter Sales Department TEL: +81-143-55-5293 FAX: +81-143-55-5295 sales@chimera.co.jp

| Main 3 products | Molding (plastic) dies, press dies, various mold components processing, precision metal machining [design, manufacture, testing] In order to meet needs for quick delivery, we stock various die materials such as NAK, SKS, SKD, high speed steel and ultra-hard materials. With our high speed cutting machining center, |

|---|---|

| Type of manufacturing | Audio-video equipment Office automation equipment Electronic parts |

| Recommended manufacturing category |

1:Die manufacturing - Plastic mold - Part processing 2:Designing - Mold designing - Injection molding die 3:Development and production of prototype/Small-scale production - Prototype processing - Plastic protocol machining 4:Development and production of prototype/Small-scale production - Grinding processing - Jig boring 5:Development and production of prototype/Small-scale production - Grinding processing - Jig grinding 6:Die manufacturing - Press die - Plate machining 7:Die manufacturing - Press die - Die set machining 8:Die manufacturing - Plastic mold - Core and cavity machining 9:Die manufacturing - Plastic mold - Thin wall injection molding die 10:Die manufacturing - Plastic mold - Cassette-type molding die |

1-10 / 22747 hits